Description

Planetary mixer: the specially developed reducer can effectively distribute the power balance to each mixing device to ensure the efficient and low-noise transportation of the mixer. At the same time, it saves more space. Compared with the traditional reducer, the maintenance space of the mixer can be increased by 30%. The specially designed mixing device makes the mixing speed faster, the mixing more uniform and there is no stacking phenomenon.

For mixing different materials, the lining plate can be cast iron, HARDOX wear-resistant plate and high wear-resistant surfacing material imported from Sweden. High nickel alloy stirring blades are more wear-resistant, and polyurethane blades are optional.

Large size inspection and repair door is convenient for maintenance and cleaning. The key safety control device ensures that when the access door is opened, even if the power switch is closed, the motor cannot run. The hydraulic unloading system is equipped with a manual door opening device, which can open the door manually in case of power failure.

The unloading door is equipped with a limit switch, which can easily set the size of the door according to needs* Three more discharge doors can be opened. From model selection to personalized customization for special applications, as well as maintenance and service, we can provide all-round technical support and guarantee.

The vertical shaft planetary mixer has the advantages of compact structure, stable transmission, novel style, excellent performance, economy and durability, convenient installation and maintenance, and there is no slurry leakage problem.

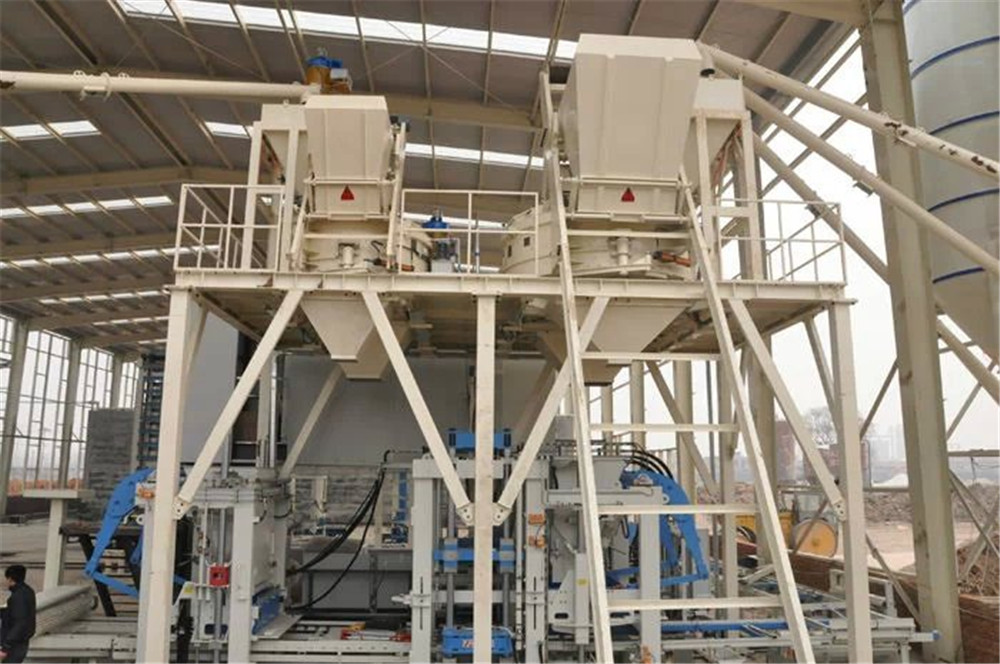

The planetary mixer is mainly composed of transmission device, mixing device, unloading device, maintenance safety device, metering device, cleaning device, etc. The transmission device adopts the hard tooth surface reducer specially designed by the company for transmission. An elastic coupling or hydraulic coupling is installed between the motor and the reducer. The power generated by the reducer makes the mixing arm do both autobiographical motion and revolution motion, and makes the scraper arm revolution motion. Thus, the mixing motion has both revolution and rotation, the mixing motion trajectory is complex, the mixing motion is strong, the efficiency is high, and the mixing quality is uniform.

The mixing plant equipped by planetary mixer can produce high quality concrete that widely used for concrete pipe, concrete panel, concrete crab stone or other precast products. It is also can supply high strength concrete UHPC(Ultra-High Performance Concrete) for construction projects

Projects

Shipment