Description

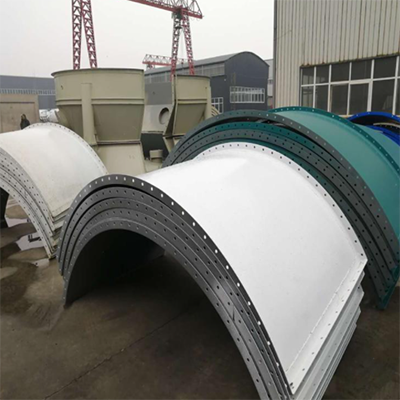

The cement silo consists of the steel structure part of the silo, ladder, guardrail, charging pipe, dust collector, pressure valve, high and low level gauge, discharge valve, etc.

The cement silo is of cylindrical structure, the bottom of which is supported by four round pipe legs, and the whole silo is of steel structure and welded; Dust collector and pressure valve are set at the top.

|

Model |

Diameter(mm) |

Height(m) |

Leg diameter(mm) |

Distance of leg(mm) |

Thickness(mm) |

Weight T |

|

50T |

3160mm |

6.5m |

219×5 |

2240mm(4legs) |

cone5mm other4mm |

4T |

|

100T |

3160mm |

10.7m |

219×6 |

2240mm(4legs) |

cone5mm other4mm |

5.5T |

|

150T |

3160mm |

15m |

273×6 |

2240mm(4legs) |

cone5mm other4mm |

8T |

|

200T |

4500mm |

11.5m |

273×8 |

3160mm(4legs) |

cone6mm other5mm |

12T |

|

300T |

5300mm |

12.7m |

325×8 |

3748mm(4legs) |

cone8mm other6mm |

17T |

|

400T |

6800mm |

11.7m |

325×10 |

4800mm(4legs) |

cone8mm other6mm |

21T |

|

500T |

6800mm |

13.5m |

325×10 |

3400mm(6legs) |

cone8mm 节8mm other6mm |

28T |

|

800T |

6800mm |

15.3m |

426×12 |

3060mm(8legs) |

cone10mm

|

4 |

Working principle of bolted cement silo:

1. When the cement silo (cement tank) is working, it shall be erected by the crane, and then placed on the pre prefabricated concrete foundation. After the cement silo (cement tank) is erected, the verticality with the horizontal plane shall be checked, and then its bottom shall be firmly welded with the foundation embedded parts.

2. After the storage bin is fixed, the cement is transported to the construction site by the bulk cement truck, and then the transmission pipeline of the bulk cement truck is connected with the feed pipeline of the cement bin (cement tank), and the cement in the tank is transmitted to the cement bin (cement tank) through the gas pressure of the bulk cement truck.

3. In the process of conveying cement to the storage bin, the operator continuously presses the button of the dust collector vibrating motor to shake off the cement attached to the dust collector bag to prevent blocking the bag and bin explosion.

4. Once the cloth bag is blocked and the pressure in the bin exceeds the pressure of the pressure valve on the top of the bin, the pressure valve can be opened to release the pressure in the bin to prevent the occurrence of bin explosion.

5. Through the high and low material levels, it can be observed that the warehouse is full and short.

6. When discharging is required, open the manual discharge valve at the bottom of the cone, and then convey the cement through the cement conveying device. In case of “arching” during discharging, press the button of the solenoid valve of the arch breaking device in time to blow air, and “arching” is used for feeding, so as to ensure smooth cement supply.

7. When the cement conveying device fails, close the manual discharge valve at the bottom of the cone to prevent cement overflow and waste.

Production instructions

1. The storage bin manufactured by our company meets the industry standard.

2. The unloading height is 1.96m and 4.2m, which can also be processed according to user requirements.

3. The capacity of cement silo includes 30t, 50t, 60t, 80t, 100t, 120t, 150t, 200t, 250t, 300t, 500t, etc