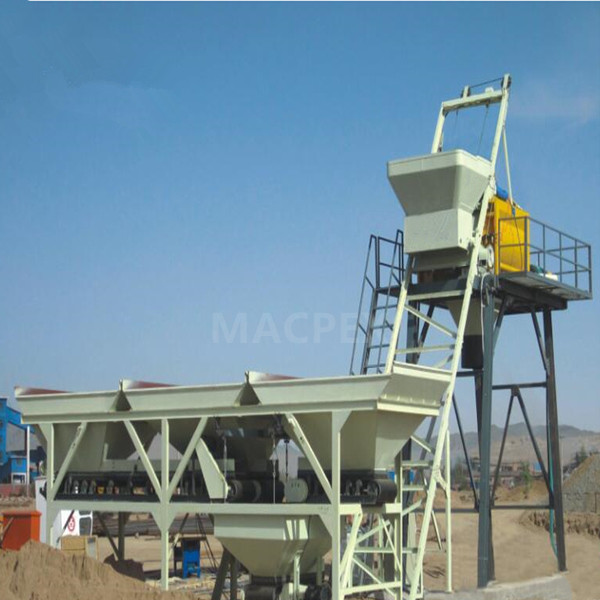

Description

The concrete mixing plant of HZS35 project, also known as 35 mixing plant and 35 plant, adopts an advanced automatic control system, integrates the application of simulation technology in the concrete field, intelligent control, automatic control and manual control, can observe and count the production process and production situation of the mixing plant and building in real time, and can be connected to the control of detecting the water content of sand and stone and the slump of concrete, It can be used for automatic on-line temperature compensation, so as to achieve the purpose of sand and water reduction. It can provide remote communication interface to transfer the data of each workstation to the office, so as to read the production process data in real time, which is convenient for management and height control.

Feature of HZS35 concrete mixing plant

(1) HZS35 station adopts combined structure and modular unit, which is very convenient for installation and relocation.

(2) JS750 double horizontal shaft forced concrete mixer is used for mixing host and aggregate lifting of HZS35 station, with good mixing quality and high efficiency.

(3)PLD1200 batching machine is adopted for aggregate batching, with accurate measurement and high production efficiency.

(4) Powder, water and admixture are measured by electronic scale, with high batching accuracy.

(5) The water supply system adopts the pressurization principle of siphon water pump to accelerate the water flow rate and spray evenly.

(6) The electrical control system adopts imported components with reliable performance, manual and automatic control and convenient operation.