Description

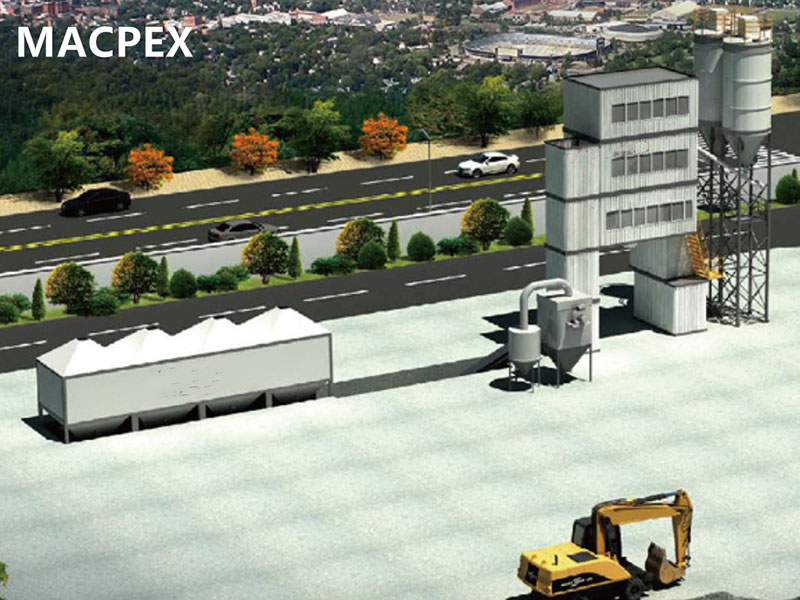

Dry concrete mortar mixing plant and dry concrete mortar production line are used to produce concrete and mortar. This belongs to mobile container dry concrete mortar mixing plant and dry concrete mortar production line, which is more convenient and movable, which is a feature of mobile container type.

Modular design, simple and fast installation: greatly reduce the hoisting cost and labor cost, save 70% of the installation time and 80% of the labor and hoisting cost compared with the ordinary dry powder mortar production line.

No civil engineering cost and cost saving: the bottom surface of the container can stand firmly on 20cm thick ordinary concrete, so as to avoid large civil engineering cost.

Small floor area and reduced plant construction: with the help of the good sealing of the container structure, there is no need to build another plant, and it can be disassembled and moved at any time.

Secondary recycling, energy conservation and environmental protection: the equipment has small installed capacity, low energy consumption and low noise. All production links are equipped with dust collection devices. The collected dust can be recycled into materials without secondary pollution.

Product advantages:

■ simple installation and fast relocation

■ no foundation design and small floor area

■ green environmental protection

■ adapt to harsh environmental conditions

Modular mortar mixing plant design, simple and fast assembly, greatly shorten the installation time of the equipment, greatly reduce the cost of labor and mechanical hoisting, and can be disassembled and moved at any time. When installing the container mixing plant, it only needs to lay the foundation steel plate according to the foundation requirements. In particular, field construction can save labor, time and other costs. At the same time, the whole station has compact structure and small floor area.

The main components of the equipment are installed in closed containers, which can effectively block the dust generated during mixing and transportation and reduce noise pollution. In case of rain, snow and sand outside, the container can effectively protect various core components and reduce faults.