Description

Description:

- Concrete mixing trailer pump by diesel power is a high-efficiency concrete mixing and conveying equipment that combines concrete mixer and conveying pump to simplify construction process and facilitate consignment. It is mainly used for civil housing construction, water conservancy dam, village road laying and foundation filling.

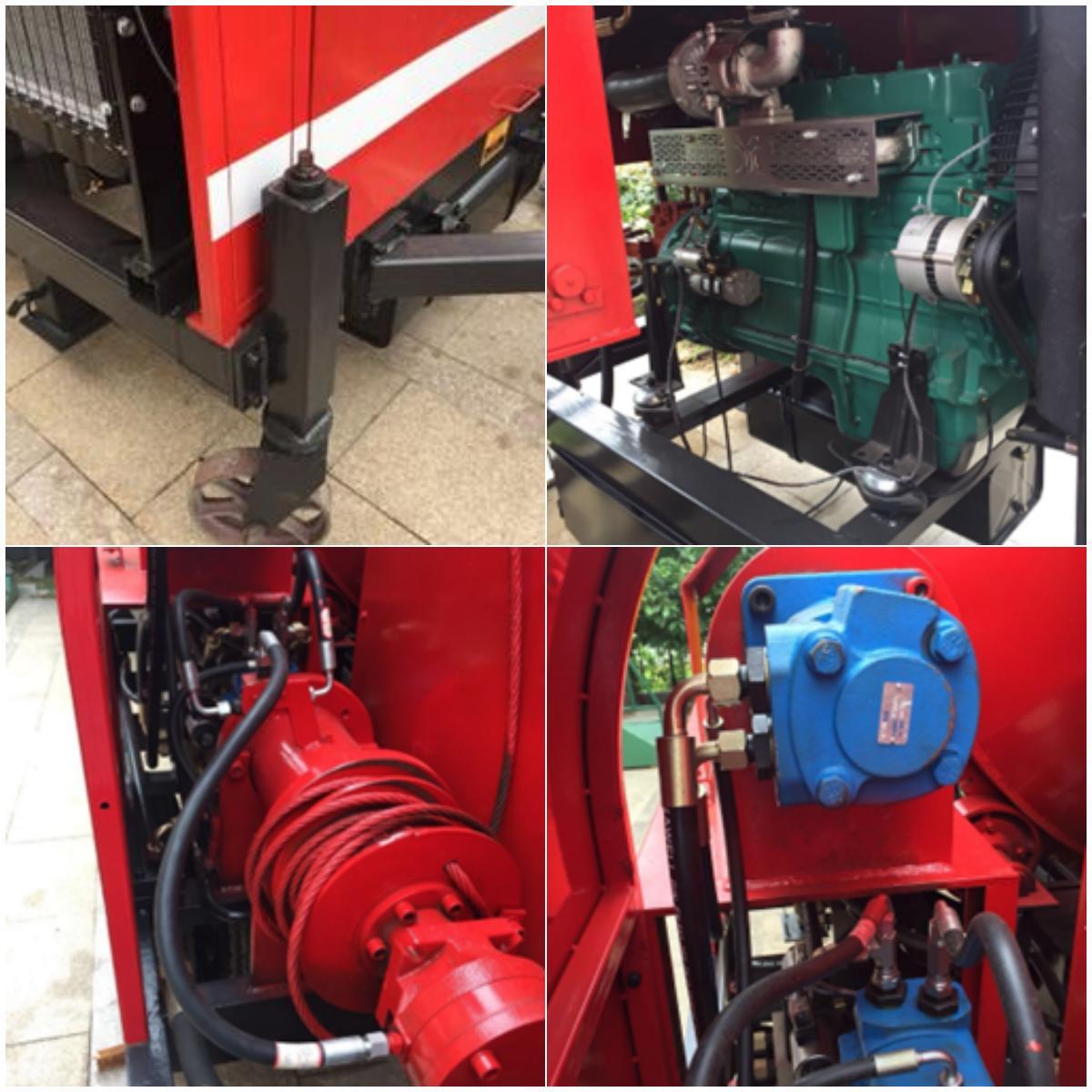

- Loading, mixing and pumping are all mechanized, reducing labor costs, and the efficiency can be increased by 4-6 times, which can effectively speed up the construction progress, reduce the construction cost and reduce the equipment space. A walking wheel is installed at the bottom, which is convenient to use.

- It has the advantages of simple operation, convenient use, remote control, simple structure, technological innovation, small floor area and can be constructed in a narrow place.

- It is widely used for housing, road and other construction projects, the diesel power can use this pump in remote area that has no electrical supply.The electrical power concrete pump with mixer also available.

- Diesel powered mixing trailer pump, also known as mixing pump or mixing delivery pump, mixing pumping machine, etc., is a movable concrete mixing plant integrating mixing system and pumping system.

- It has the characteristics of mobility, flexibility, convenience, high efficiency and good concrete quality. It is especially suitable for on-site concrete mixing construction in small towns and rural construction markets, and can be widely used in water conservancy, roads Bridge, tunnel, slope protection, foundation, house and other concrete pouring projects with inconvenient construction and long distance are new modern construction machinery between mixing plant and traditional methods, which has incomparable advantages.

Diesel generator combination can be used in remote areas.

- The vertical pumping is 50m and the horizontal pumping is 260m, which saves labor. One person operates and three people cooperate

Reduce labor force, labor intensity, convenience, Mixing and pumping are combined into one, and the hydraulic outrigger is designed to move faster.