Operation guidance for foam making machine:

1. connect every part like the picture

The yellow pipe with filter screen put into the finished dilute foam agent barrel ( before use the foam agent : water is 1:40 to dilute),

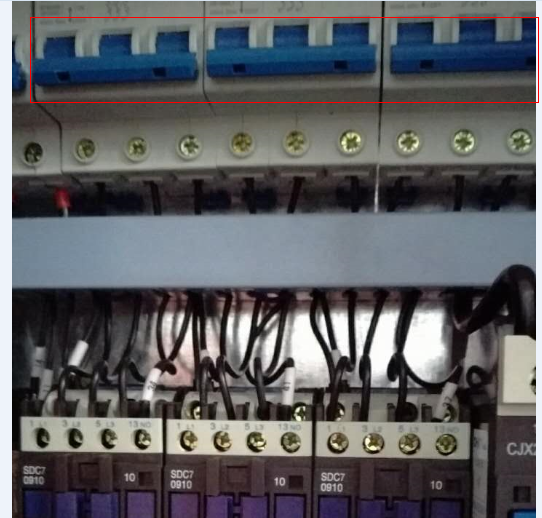

2. 1control panel

the red mark to open up .

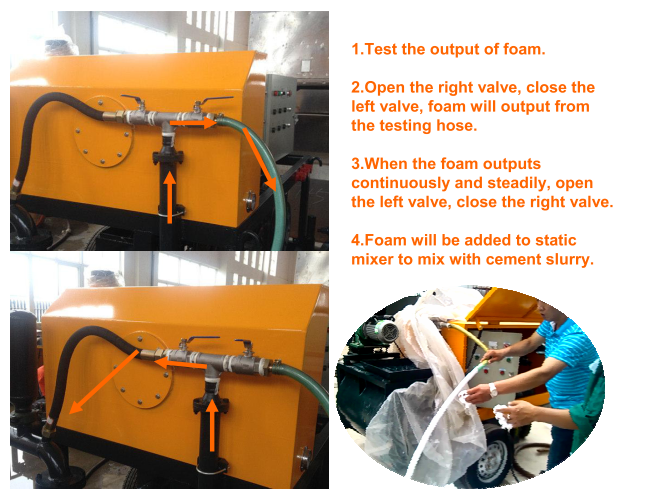

2.2 foaming system

Before run this machine , must testing foaming . press ( foam pump on) button start to output the foam like this picture .

2.3

Then press the press ( foam pump off ) button again then finish the foaming test , and close the foam generator,

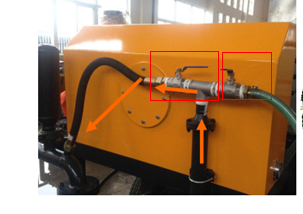

During this working you must keep the value like the picture before press ( foam concrete pump on) button.

2.4

1. press (water pump on ) button water pump will start to pump water to the mixer , when the water pump into the 2/3 mixer .

( usually we put 150kg cement 50kg sand 90L water , frequency convert adjust 40HZ then according this density adjust the rario of each material )

- then press (Mixer on) then the mixer will star to work .

- then press ( Aggregate pump on) button , then the conveyor start to convey the cement to the mixer

4. After mixer work about 2-3min

Then press ( foam pump on) button again then the foam generator start to work . after press (foam pump on) in 1 second pls HURRY TO press ( foam concrete pump ) button

5. then the cement slurry will be mixed with the foaming to finish foam cement and start to pump foam cement.

6.when finish the work , press the button again , ( foam pump off) ( Aggregate pump off) , but let the water pump and mixer work , keep adding water to the mixer and pump out to wash the machine . after washing the machine then press (aggregate conveyor off ) ,( mixer off )and (foam concrete off)

By the way , matters need attention :

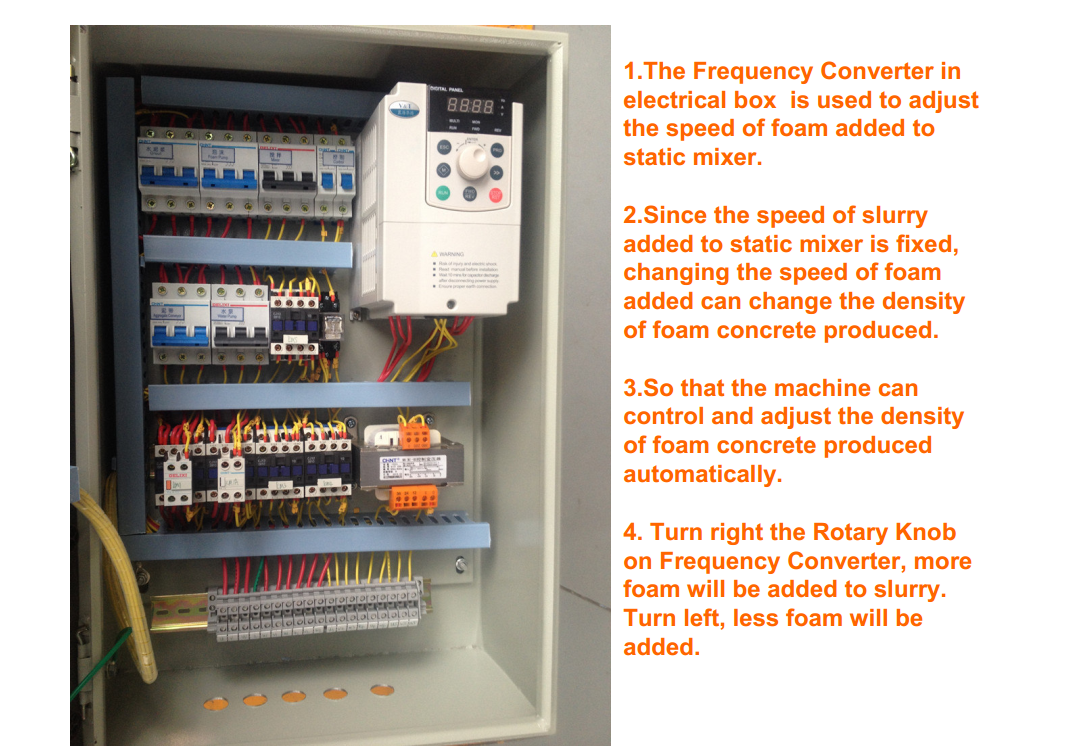

1.frequency changer dont adjust by yourself , before delivery our engineer already adjust well .

2.After working , stop other part and keep adding water to wash and clear the machine . this is very import , and close the left valve to avoid the mortar back to the foam generator

3Generally the frequency changer adjust 50HZ the density is 400-500kg/m3 if less HZ the foaming will be less , More HZ the foaming can product more .

4. if just pump mortar , can add a little foaming to lubricate the pipe and help to pump easily mortar .

5. Usually Check equipment and add water or lubricating oil to the the water tank