The planetary mixer has stable operation and high efficiency, which meets the high requirements of material mixing production in the refractory industry. The unique planetary mixing technology enables better mixing of refractory materials, reduces mixing time, improves mixing advantages, and promotes the completion of higher quality production in the industry. The advent of the planetary mixer has become an indispensable part of the “Puzzle” of the refractory industry!

Planetary mixer

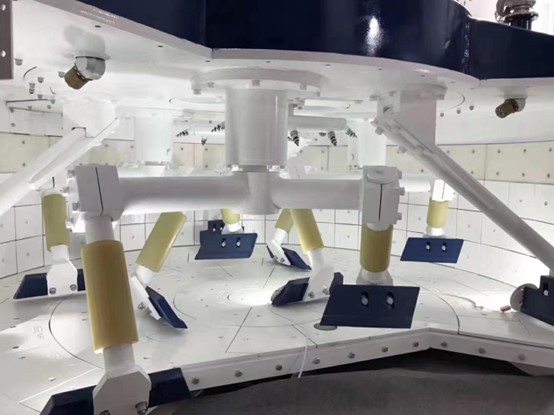

The durable product design of the new refractory mixer – planetary mixer has greatly improved the service life of the refractory mixing equipment and greatly reduced the mixing wear of the equipment during the mixing process of materials. The wear-resistant materials selected for the blades and lining plates have also improved the wear resistance and durability of the planetary mixer.

In addition, the planetary mixer can also promote the rapid mixing production of refractory materials through the control system. Various optional devices can be configured according to the different mixing requirements of the industry, such as temperature and humidity tester, high-pressure cleaning device, lifting hopper and metering device. The rich mixing model makes the planetary refractory mixer more widely used in the industry.

The specially designed single motor drive ensures the consistency of power output of the planetary mixer, which is the premise to achieve high uniformity of refractory mixing. In addition, the unique planetary mixing mode is an upgrade and innovation of Qingdao Dikai on the basis of the traditional refractory mixer.