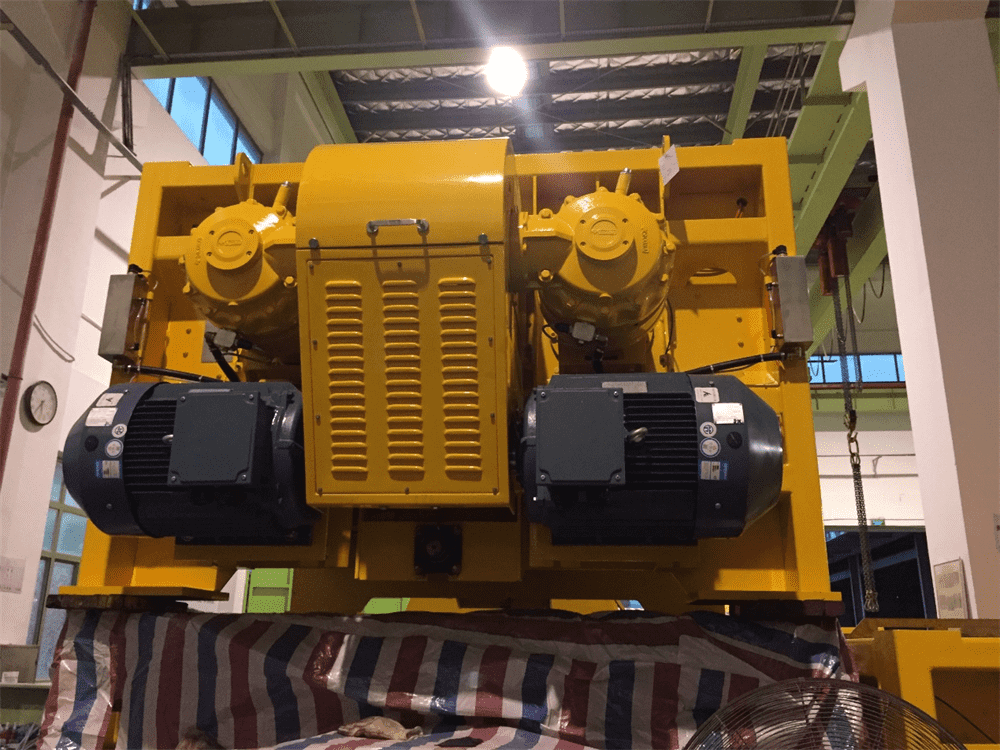

Two sets SICOMA mixer loaded successful at workshop and will shipped to customer by sea transportation. The SICOMA MAO series mixer is widely used in the world for the concrete ready mix factory with mature design and excellent performance.

1. Check before use

Press the switch before closing the knife switch to check whether the operation is flexible. Whether the operation of vibrator, drum and paddle is normal. Winding of steel wire rope on drum; Whether the lifting of waste discharge platform is normal. If any fault is found, notify the electromechanical team for treatment. After treatment, it can be used.

2. Do not feed too much at one time. Feed according to the proportion and pay attention to the water cement ratio. The mixing shall be uniform, and the mixing time at one time shall not be less than one minute. The normally mixed concrete shall be very thick porridge.

3. A specially assigned person shall be assigned to start the machine. The driver shall be familiar with the working principle of each operating system, and stop the machine for inspection immediately in case of any fault.

4. The electrical parts shall be taken care of, and the cables shall be well protected to prevent damage.

5. The mixer shall be leveled and no one shall stand under the hopper of the mixer to prevent injury when falling flowers and water under the hopper.

6. During temporary rail stop, the mixer shall be started regularly (every 20 minutes) to prevent concrete solidification or pour out the concrete in the drum, and the drum shall be washed with water.

7. After concrete pouring and shutdown, the drum and mortar outside the machine shall be washed and cleaned with water in time. The lower part of the feed hopper shall be cleaned once a shift so that the feed can fall to the specified position when it is lowered, and a layer of oil shall be coated on the surface for next use.

8. Seriously implement the shift handover system, and explain the operation of working machines and precautions clearly